All Products

-

Stainless Steel Coil

-

Cold Rolled Steel Coil

-

Stainless Steel Strip

-

Stainless Steel Sheet Plate

-

Stainless Steel Pipes Tubes

-

SS Steel Rod

-

Industrial Galvanized Pipe

-

Carbon Steel Tube

-

Stainless Steel Fittings

-

Stainless Steel Angles

-

Stainless Channel Bar

-

Stainless Steel I Beam

-

Copper Metal Roll

-

Aluminum Plate Sheet

-

Aluminum Strip Coil

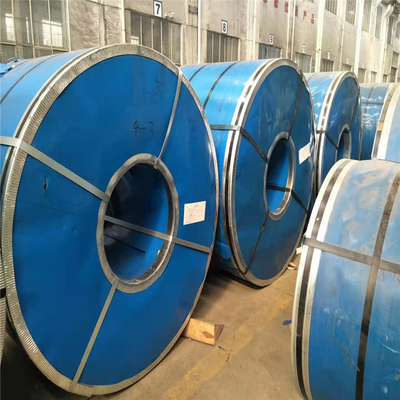

ASTM 201 304 316L Stainless Steel Coil Roll 430 0.2 0.5 0.9 1.2 12 20mm 309S 304L

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Application | Power Equipment Unit, Power Plant, Etc., Power Equipment Unit, Power Plant, Etc. | Thickness | 1.0 1.2 1.5 2.0 2.5 3.0 4.0 5.0 6.0 8.0.etc, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, Etc. |

|---|---|---|---|

| Standard | ASTM, ASTM | Width | 1000/1220/1250/1500/1530/1810, 25/50/100/200/400/500/600/800/1000/1220/1250/1500/1530/1810 |

| Certificate | API, Ce, ISO9001 | Grade | 201/304/316L/321/310S.etc |

| Tolerance | None | Processing Service | Welding, Punching, Cutting, Decoiling |

| Steel Grade | 304N, 310S, S32305, 316Ti, 316L, 321, 410S, 347, 430, 309S, 304, 409L, S32101, 904L, 304J1, 317L, C276, 2205, 2507, S32168, 321H, 347H | Surface Finish | 2B/NO.1/1D |

| Delivery Time | 7 Days | Product Name | Stainless Steel Band |

| The Material | 201/304/316L/321/310S/904L/2205/2507/C276/309S/304L/316Ti/317L | Quality Grade | The Real Thing |

| City Of Warehouse | Wuxi, Jiangsu Province | Processing Services | Cutting/Decoiling/Punching |

| Port | In Shanghai Port | ||

| Highlight | 304 316L Stainless Steel Coil longgang,ASTM 201 Stainless Steel Coil longgang,Stainless Steel Coil roll 430 longgang |

||

Product Description

ASTM 201/304/316L 0.2 0.5 0.9 1.2 12 20 Mm Stainless Steel Coil Wholesale 309S/304L Stainless Steel Coil

|

Item

|

Surface finishing

|

Surface finishing methods

|

Main application

|

|

NO.1

|

HR

|

Heat treatment after hot rolling,pickling,or with treatment

|

For without the purpose of the surface gloss

|

|

NO.2D

|

Without the SPM

|

Method of heat treatment after cold rolling,pickling surface roller with wool or eventually a light rolling a matte surface

processing

|

General materials,building materials

|

|

NO.2B

|

After SPM

|

Giving NO.2 processing materials appropriate method of cold light sheen

|

General materials,building materials(most of the goods are processed

|

|

BA

|

Bright annealed

|

Bright heat treatment after cold rolling,in order to be more shingy,cold light effect

|

Automaotive parts,home appliances,vehicles,medical equipment,food equipment

|

|

NO.3

|

Shiny,coarse grain processing

|

The NO.2D or NO.2B processing timber NO.100-120 polishing abrasive grindding belt

|

Building materials,ketchen supplies

|

|

NO.4

|

After CPL

|

The NO.2D or NO.2B processing timber NO.150-180 polishing abrasive grindding belt

|

Building materials,ketchen supplies,vehicles,medicals

|

|

240#

|

Grinding of fine lines

|

The NO.2D or NO.2B processing timber 240 polishing abrasive grindding belt

|

Kitchen appliances

|

|

400#

|

Close to BA luster

|

The MO.2B timber 400 polishing wheel polishing method

|

Building materials,kitchen utensils

|

|

HL(Hairlines)

|

Polishing line having a long continuous processing

|

In a suitable size(usually mostly No.150-240 grit)abrasive tape for as long as the hair,having a continuous processing methond of

polishing line.

|

The most common building materials processing

|

|

NO.6

|

NO.4 processing less than the reflection ,the extinction

|

NO.4 processing material used for polishing Tampico brushing

|

Building materials ,decorative

|

|

NO.7

|

Highly accurate reflectance mirror processing

|

NO.600 of the totary buff with a polishing

|

Building materials ,decorative

|

|

NO.8

|

highest relfectivity mirror finish

|

Fine particles of abrasive material in order polishing,mirror polishing with a polishing

|

Building materials ,decorative,mirrors

|

|

Place of Origin

|

China

|

|

Model Number

|

LG103

|

|

The Material

|

201/304/316L/321/310S/904L/2205/2507/C276/309S/304L/316Ti/317L

|

|

Standard

|

ASTM

|

|

Quality Grade

|

The Real Thing

|

|

City of Warehouse

|

Wuxi, jiangsu province

|

|

Type of Goods Sold

|

The spot

|

|

Thickness

|

0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.2, 1.5, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 8.0, 10, 12, 14, 16, 18, 20mm

|

|

Surface finish

|

2B/NO.1/1D

|

|

Width

|

1000/1220/1250/1500/1530/1810

|

|

Processing services

|

Cutting/Decoiling/Punching

|

|

Application

|

Power equipment unit, Power plant, Electrical Equipment Company, Machinery factory, Thermal power plant, Automobile manufacturing, Construction engineering, Pipeline engineering, Building decoration,

shipyard |

1.What's the order process?

1)Inquiry---provide us all clear requirements (total qty and package details).

2)Quotation---officaial quotation from with all clear specifications from our professional team.

3)Marking Sample --- confirm all quotation details and the final sample.

4)Production---mass production.

5)Shipping---by sea or by air.

2.What terms of payment you use?

As for the payment terms,it depends on the total amount.

3.How do you ship the products?

By Sea ,By Air ,By courier, TNT , DHL, Fedex, UPS Etc. It is up to you .

4.What is the average delivery time?

Sample usually takes about 3-7 days depending on product type. Bulk order usually takes about 7-15 days.

5.How would I get a price list for a wholesaler ?

Please e-mail us, and tell us about your market with MOQ for each order. We would send the competitive price list to you ASAP.

Recommended Products